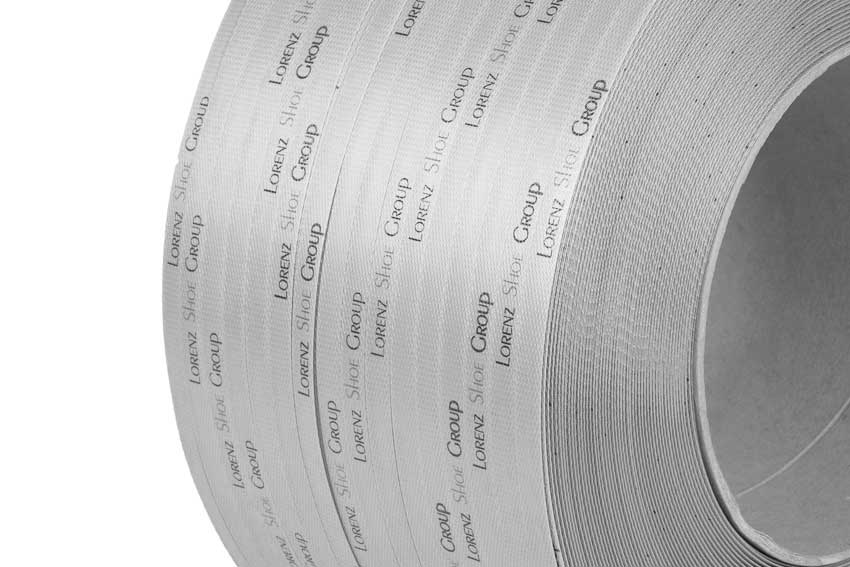

The following specifications set our printed PP strapping apart:

- High-quality “off-set” printing with up to 3 colours

- Printing length up to 400 mm

- No loss of quality compared to unprinted bands

- Suitable for all types of machines

- Printing on band widths from 9 – 18 mm possible

Our printed PP strapping has the big advantage that there is no difference in quality compared to unprinted strapping. We use our time-tested “Inline” process for printing. The printing takes place directly during production.

Typically, finished rolls from stock are printed to order. The problem with this standard procedure is that the PP band is given a “double sabre” when wrapped, i.e. it has a double curve in the band. The sabre plays an important role when used in fully automatic strapping machines, because these depend on a straight band during insertion.

In contrast to conventional printed PP strapping, our printing process has the big advantage that there are no differences in quality compared to unprinted strapping. This time-tested printing method is known as the “inline” process. Printing therefore takes place during production and does not require any coiling of the band.

Vorteile von bedrucktem PP Umreifungsband

- Allows product presentation even where space or possibilities for cardboard printing are lacking

- Saves costs and the need for additional printing of packaging materials

- Protects your goods against theft or falsification

- Simplifies the identification and differentiation of your goods during transportation, thus increasing reliability and reducing the frequency of errors

Anfrage

Do you need more information about this product?

Then do not hesitate to send us a message. We will get in touch with you as soon as possible.