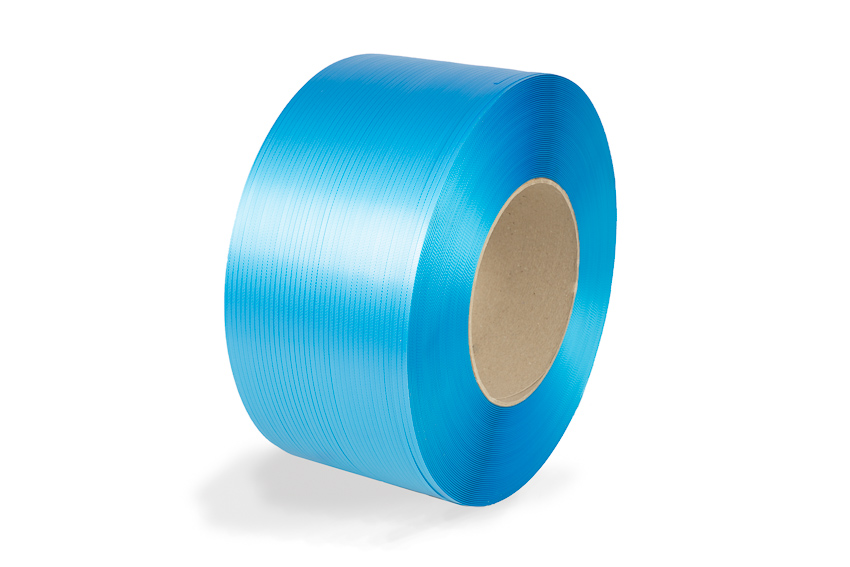

Strapping: Size 5 – 6 mm

- Light packages

- Embossed and smooth type

- Standard: black, white

Application example

Strapping of printed products

Specification

Ø 62, 150, 184, 200, 280

2 spools/box

24;30 boxes/pallet

Anfrage

Our consultants are always at your disposal for questions and comments. We look forward to your inquiry.

KontaktStrapping: Size 7 – 9 mm

- Light to medium-weight packages

- Standard: black, white

Application example

General package shipping

Specification

Ø 150, 184, 200, 280

2 spools/box

24;30 boxes/pallet

Anfrage

Our consultants are always at your disposal for questions and comments. We look forward to your inquiry.

KontaktStrapping: Size 10 – 12 mm

- Medium-weight packages

- Standard: black, white

Application example

Pallet restraint

Universal strapping jobs

Specification

Ø 150, 184, 200, 280

2 spools/box

24;30 boxes/pallet

Ø 406

1 spool/box

52 boxes/pallet

Anfrage

Our consultants are always at your disposal for questions and comments. We look forward to your inquiry.

KontaktStrapping: Size 12 – 12.7 mm

- Very heavy packages

- Standard: black, white

Application example

Pallet restraint

Universal strapping jobs

Specification

Ø 200, 280

2 spools/box

24;30 boxes/pallet

Ø 406

1 spool/box

52 boxes/pallet

Anfrage

Our consultants are always at your disposal for questions and comments. We look forward to your inquiry.

KontaktStrapping: Size 15 – 18 mm

- Heavy packages

- Standard: black, white

Application example

Strapping goods with a sensitive surface

Specification

Ø 200, 280

2 spools/box

24;30 boxes/pallet

Ø 406

1 spool/box

52 boxes/pallet

Anfrage

Our consultants are always at your disposal for questions and comments. We look forward to your inquiry.

KontaktPET strapping: Size 12 – 19 mm

- Securing heavy pallets

- Standard colour: green

Application example

Steel and timber industry

Pallet restraint

Specification

Ø 200, 280

2 spools/box

24;30 boxes/pallet

Ø 406

1 spool/box

52 boxes/pallet

Anfrage

Our consultants are always at your disposal for questions and comments. We look forward to your inquiry.

KontaktSpecial core 12 mm

- Mobile manual strapping

- Medium-weight to heavy packages and pallets

Specification

1 spool/box

60 boxes/pallet

Anfrage

Our consultants are always at your disposal for questions and comments. We look forward to your inquiry.

KontaktThe following properties are decisive for the quality of PP strapping

A distinction is made between two production processes:

- Cut bands from a wide foil (11.1 mm Signode)

- Individually extruded bands; up to 16 pieces side by side

- There is a x mm band width (machine guidance x mm)

- Band tolerance (x.4 – x.8 mm)

The width of the band can be determined by an electrical calliper.

The thickness only plays a minor role in the measurement of the band, because:

- Tension rollers can be adjusted to the band thickness in the machine

- Adjusting for band thickness is usually possible on all machines

The thickness is measured by the points of an electrical calliper.

Tear resistance, or breaking load, is the force required to tear a PP strapping band:

- Normally you will be given tear resistance in Newtons or kilograms

- The conversion factor is: 1 kg = 9.81 N

The exact tear resistance can only be reliably measured in a test laboratory.

The following statements generally apply to the weight per metre:

- The weight of the respective PP strapping per metre

- The lighter the band, the lower the tear resistance

- The price is determined by the weight per metre and the tear resistance

The weight per metre is determined using a highly sensitive scale.

The elongation at break indicates the percentage by which the PP strapping can be extended in relation to its total length before it tears. General rule of thumb:

- PP strapping can be stretched from 18% to 22%

- Special flex strapping achieves an elongation at break of up to 50%

- The stress resistance varies according to the material composition and defines the amount of elongation that decreases when the stress is reduced or released

The exact elongation at break can only be reliably measured in a test laboratory.

Generally, PP strapping comes out of the extruder with a smooth surface:

- The final surface structure is embossed with an embossing roller

- Fine to coarse surface embossing is possible with embossed bands

- The embossing allows the PP strapping to be sealed

The embossing can be judged by optical checks on the strip.

The raw material of PP strapping is transparent. General rule of thumb:

- Different colours can be achieved with mixed colour additives

- Colour additives reduce the risk of the PP strapping splitting

- Splitting is understood to mean the breaking apart of the band in the longitudinal direction (fibres/cracks in the molecular chains), which can occur under mechanical stress (e.g. cutting bands under tension).

Chemie-Faser Ebnat AG offers a wide range of available colours.

Inner diameter and coiling width distinguish the cores from each other. The following generally applies:

- The core and the side plates are usually made of cardboard

- There are about 20 different types of cores on the market today

- The most important core sizes are: 62/160, 200/190, 280/190, 406/150

The so-called “sabre” is the curvature of the PP strapping. The sabre has a strong effect on the quality:

- An excessively large sabre can lead to malfunctions or machine failure in automatic strapping machines

- Bands that have been wound imprecisely or stored for too long retain some of the deformation during processing. This can impair cargo safety

Our printed PP strapping has a very low sabre thanks to the inline process, because the bands only have to be wound once.

The equipment you use is crucial in choosing the right band:

- Every company has a different purpose for PP strapping bands

- Is a manual device used with sealing sleeves?

- Does the customer need bands that can be used in semi-automatic or fully automatic machines?

- The requirements on the bands vary depending on the application, e.g. different bands are required in the stone industry than in the printing industry

In order to deliver the perfect band for every application, Chemie-Faser Ebnat AG offers approx. 800 different types of PP strapping bands.